M. Odumenya, S.J. Krikler, A.A. Amis

292

femoral resection is set and not adjustable.

Unfortunately, such inflexibility does not reflect

real life clinical practice in which gross

variability is encountered. In reality, when

confronted with a severely worn, irregularly

shaped distal femur, such standard instru

mentation will not produce the ideal surface to

fit a standard trochlear component. In many

cases, some hand sculpting of the distal femur

is required to get the standard implant to sit

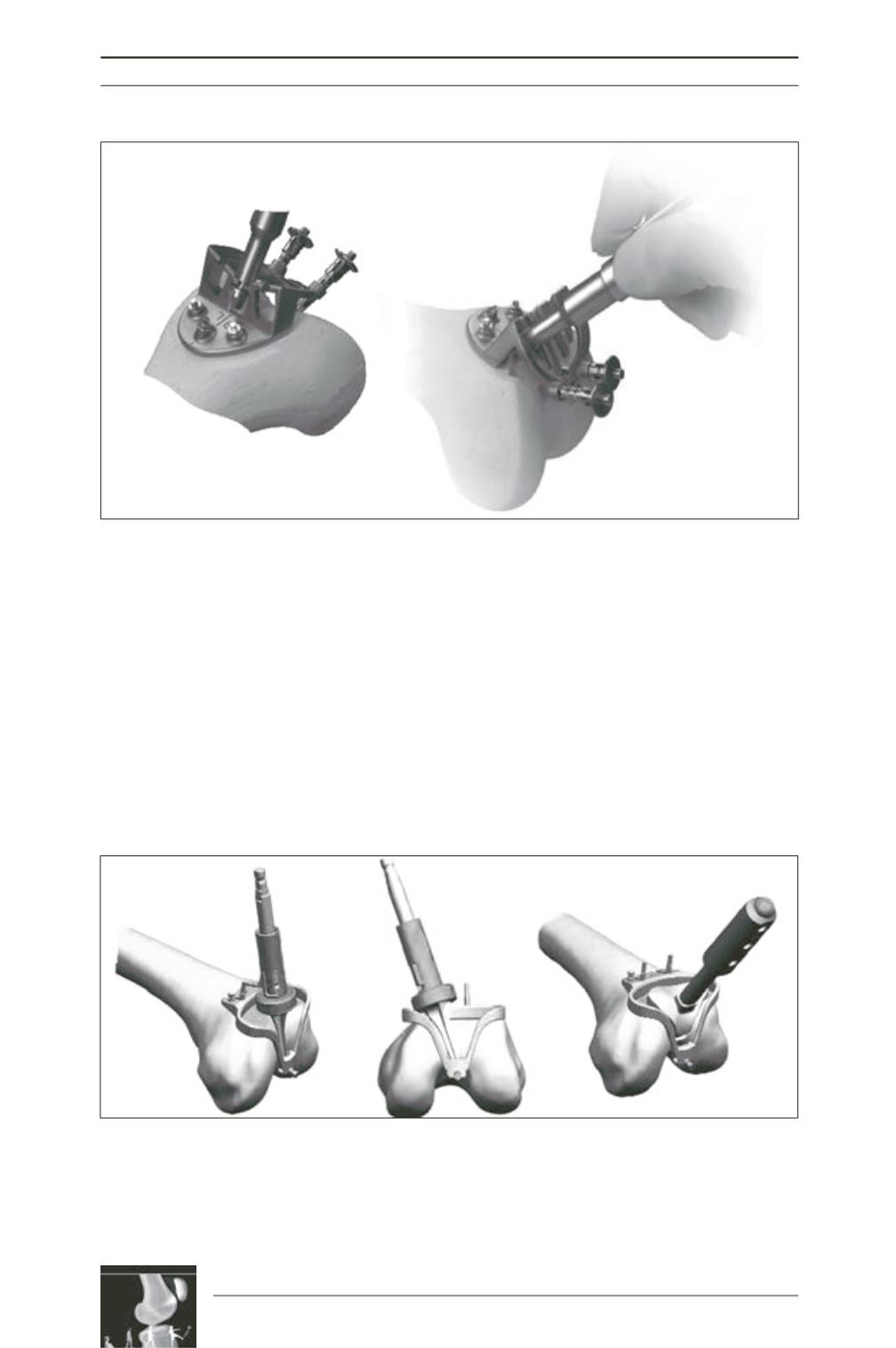

perfectly. For these reasons, the Journey PFA

system offers the surgeon the option of

adjusting the femoral resection depth after the

jig is fixed in position and thus may minimize

the need for the additional freehand fashioning

(see fig. 4A-C).

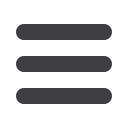

Fig. 3A-B : Zimmer PFJ milling guide. [A] Burr guard of milling handpiece placed within the central track of

the milling guide. [B] Milling handpiece held perpendicular to milling guide. Slight deviation from this

position due to toggling or binding may potentially result in loss of alignment and an inaccurate resection.

Permission to use images granted by copyright owners© 2012 Zimmer Inc.

Fig. 4A-C : Journey PFJ reamer guide. [A] Yellow standard ream sleeve on reamer shaft is used to achieve

sufficient depth by placing the reamer tip into the round indentation in the reamer guide and reaming from

medial-lateral-medial. [B] Completion of reaming is indicated when the reamer sleeve is in continuous

contact with the reamer guide throughout the range of motion. [C] Trochlear depth gauge is used to

determine adequacy of reaming depth. If more bone is required, other sleeves are available to increase the

depth and width of reamed surface area.

Permission to use images granted by copyright owners Smith & Nephew®.

A

A

B

C

B