C. FINK, M. HERBORT, P. GFÖLLER, C. HOSER

122

is outlined with a scalpel, cutting down to the

patella. Next an oscillating saw with a narrow

blade (0.5-0.7 cm) and a chisel are used to

harvest a bone plug 1.5 cm long with a width

and thickness conforming to graft geometry. To

avoid patellar fractures, it is advisable (as in the

conventional harvesting technique) to finish by

sawing parallel to the anterior patellar surface

in a proximal-to-distal direction with the

narrow saw blade (fig. 2). At that point the

bone plug is easily mobilized with a chisel. The

free end of the tendon is whipstitched with two

nonabsorbable N° 2 lead sutures. The bone

plug is tailored to form a rectangle of the

desired size. Rounding the proximal corners of

the bone plug will facilitate later graft passage

into the joint. Two 1.5 mm holes are drilled in

the bone plug, which is then tied to a

FlippTack® fixation button (Karl Storz,

Germany) with a nonabsorbable suture (e.g.

Fibre Wire®, Arthrex Naples FL).

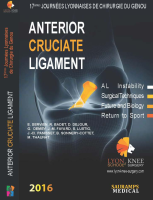

Fig. 1:

(

a

) Subcutaneous advancement of the tendon knife. The cutting edges are spaced at the desired

graft width. (

b

) Insertion and advancement of the 5 mm tendon separator. (

c

) Subcutaneous advancement

of the quadriceps tendon cutter.

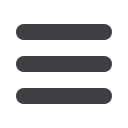

Fig. 2:

Harvesting the bone plug with

the oscillating saw. The last cut is

made in a proximal-to-distal

direction, tailoring the thickness of

the bone plug to the graft thickness.

b

a

c