C. FINK, M. HERBORT, P. GFÖLLER, C. HOSER

124

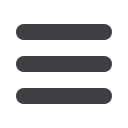

smooth surface of the rasp should face the

posterior cruciate ligament to protect that

structure from injury. A socket is formed by

driving the rasp in slowly to a depth of

approximately 25-30 mm (1 cm longer than the

bone plug). The rasp is then tapped back out,

and if necessary a dilator of the same

dimensions is inserted using the same

technique.

Tibial Bone Tunnel

The tibial drill guide is introduced through the

medial arthroscope portal. Then a vertical or

horizontal skin incision approximately 1.5 cm

long is made medial to the tibial tuberosity. The

first guide wire is now drilled in through the

center of the drill sleeve, and its relation to the

roof of the intercondylar notch is evaluated by

extending the knee. If the wire is correctly

placed, the guide sleeve is removed and a

cannulated 10 mm (or 12 mm) drill bit is

advanced over the wire. It is predrilled to a

depth of 0.5-1 cm to create a countersunk bed

for the later placement of an EndoTack® (Karl

Storz, Germany). Now the drill sleeve is

reintroduced and fixed securely in the predrilled

hole. Depending on the position of the first

guide wire in relation to the notch roof, a

second guide wire is drilled in parallel to the

first at a slightly more anterior or posterior site.

Next, each wire is overdrilled with a 5 mm drill

bit (for a planned 5.5 x 9.5 mm tibial tunnel) or

a 5.5 mm drill bit (for a 5.5 x 10.5 mm or

12.5 mm tibial tunnel. Both wires are removed,

and any bony bridges that remain between the

drill holes are disrupted with a shaver. Now a

guide wire is inserted for orientation purposes,

and a rasp of the correct width (8 or 10mm) is

carefully driven into the tunnel. Finally a tibial

dilator of the appropriate size is carefully

tapped into place to complete the tibial tunnel

(fig. 5).

Since the placement of a rectangular tibial bone

tunnel is more technically demanding, a

conventional round tunnel may also be created.

Fig. 4:

The rasp (8 or 10 x 5 mm) is driven into the bone tunnel with the knee flexed approximately 110°. The

instrument should be parallel to the tibial plateau, and its smooth surface should face the posterior

cruciate ligament.