C.H. BROWN

146

• These steps allow a tibial tunnel of a known

length to be drilled, allowing the issue of

graft-tunnel length mismatch to be addressed.

• The tibial tunnel is initially drilled with a

small diameter drill bit such as the 4.5 or

5mm fully fluted drill bit. The guide pin is

repositioned eccentrically in the desired

direction within the drilled tunnel using a

small clamp inserted through the AL portal,

and the tunnel is sequentially drilled by 1mm

increments up to the final diameter of the

tibial tunnel. These steps allow the tibial

tunnel to be positioned as far medially in the

tibial attachment site as possible.

GRAFT TENSIONING

At the present time, the optimal graft tension

and knee flexion angle for a single-bundle ACL

reconstruction are unknown. The usual graft

excursion pattern for a femoral tunnel

positioned near the center of the ACL

attachment site results in the ACL graft

tightening (pulling into the tibial tunnel) during

the last 30 degrees of extension. In this

situation, the graft is fixed at 20 degrees of

flexion with a posterior force applied to the

anterior tibia to hold the tibia in a reduced

position. A spring-loaded tensioning device is

used to tension the ACL graft. For 5-strand

hamstring tendon grafts, a 60N load is applied.

For 6-strand hamstring tendon grafts, a 70N

load is applied.

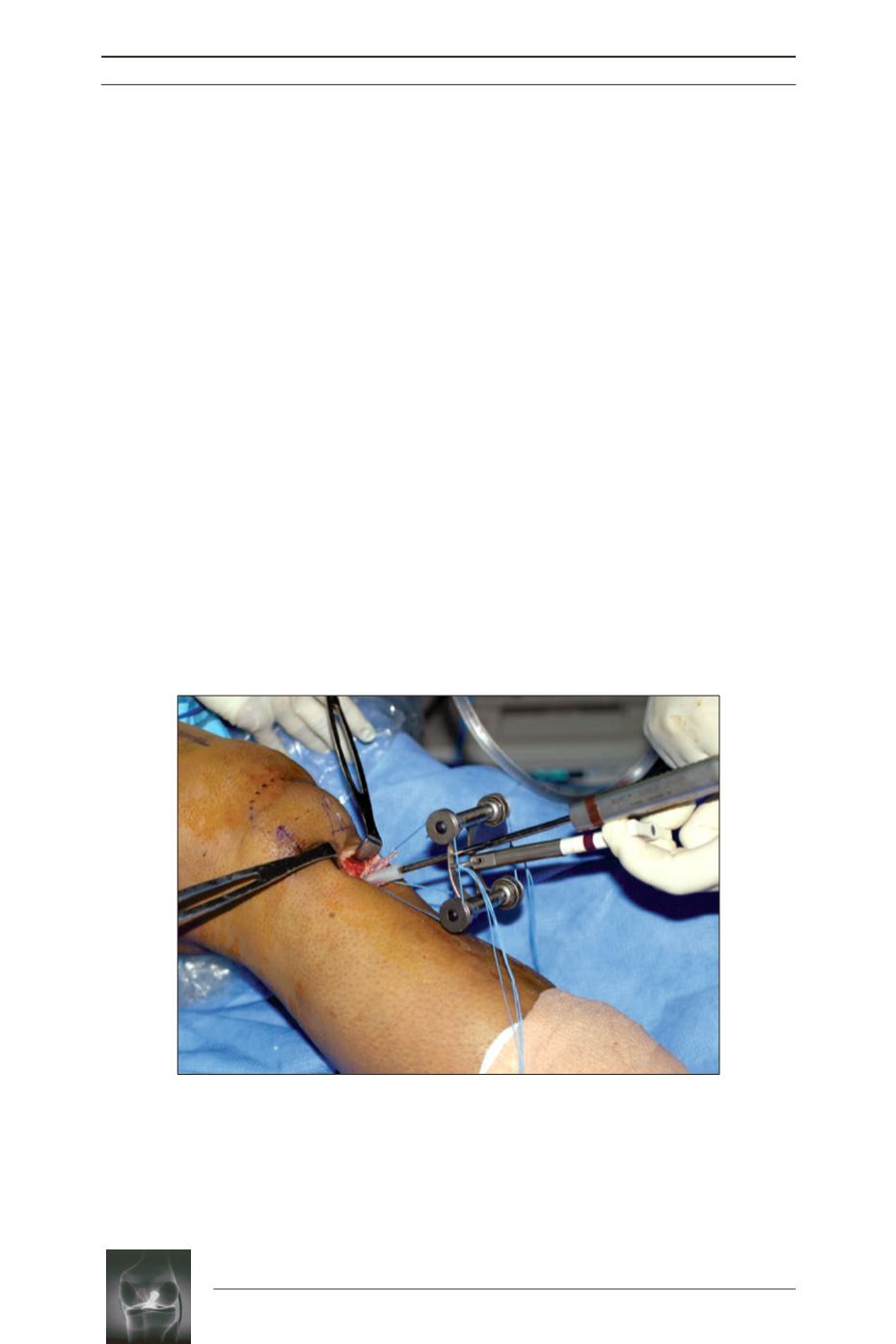

GRAFT FIXATION

The graft is fixed with a tapered 7-9mm or

8-10mm, 30mm long bioabsorbable inter

ference screw (fig. 15).

Fig. 15