S. Lustig, P. Neyret

46

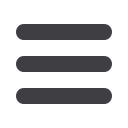

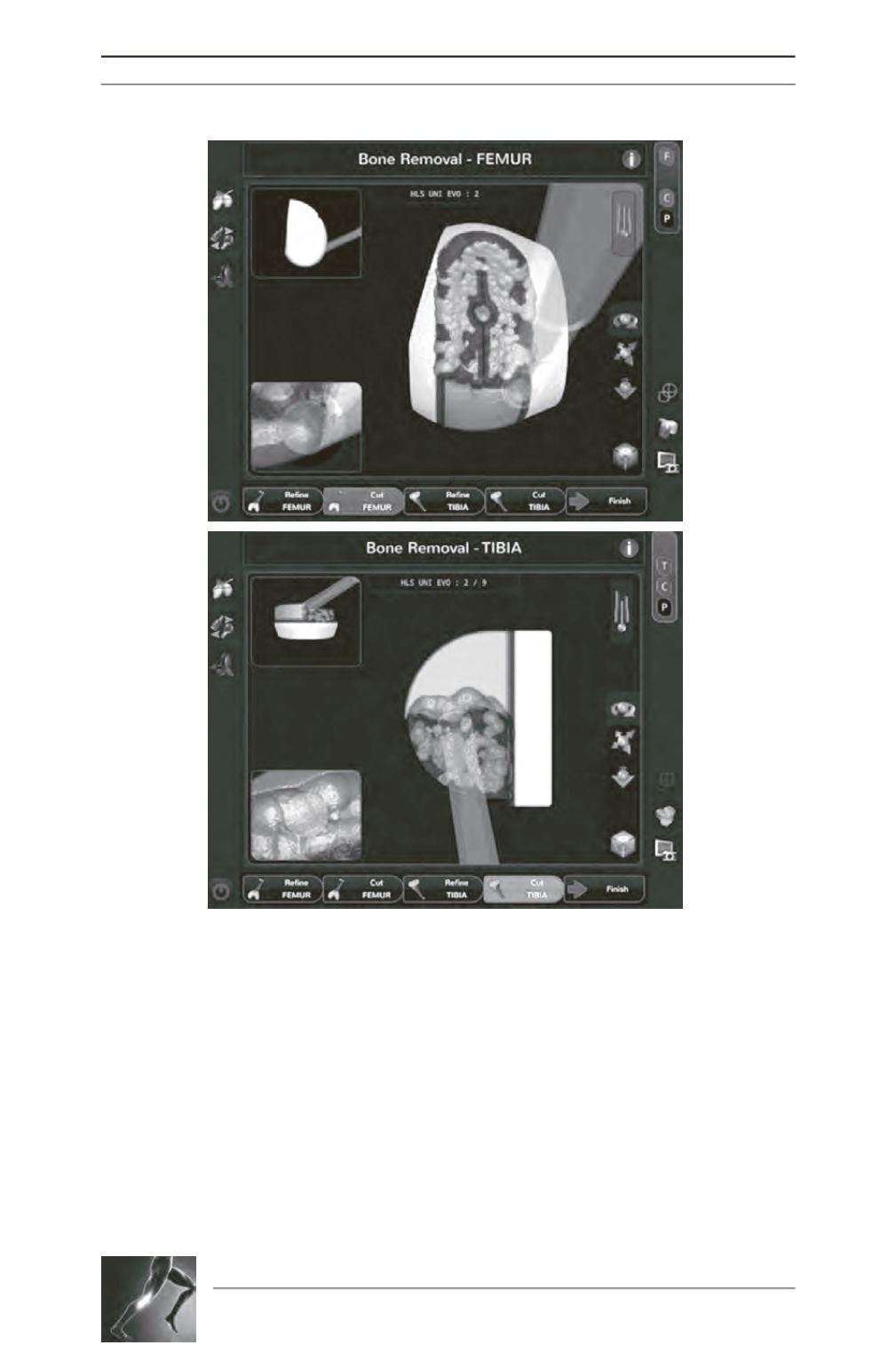

Bone preparation is performed per the

manufacturer’s recommended technique for

robotic UKA with the Tornier HLS UNI

Evolution implants. The femoral component,

with a central lug and keel, is impacted rigidly

onto the prepared bone surface and the slotted

trough and peg hole on the femoral condyle

optimized positioning of the component. The

tibial implant in this particular design is a

cemented unconstrained all-polyethylene insert.

This implant design has reported good clinical

and radiological results [2]. It was designed

without lugs or keel to allowvariable positioning

on the AP axis based on intraoperative

assessment of positioning relative to the femoral

component. Once the gap balance through a

range of motion is checked with the trials

(fig. 5). both components are cemented (fig. 6).

Fig. 4 : (A) Femur and (B) tibia cutting screens show midcutting. The

yellow surface is the “target” surface, green surface indicates 1mm of

bone still to be removed, blue surface indicates 2mm of bone still to be

removed, and the purple surface indicates 3mm or more bone still to be

removed.

A

B