Robotic surgery and intelligent intruments - Patellofemoral Arthroplasties

53

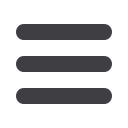

When doing preoperative planning, it becomes

evident that in certain severe trochlea dysplasia

cases it is impossible to fit any of the off the

shelf commercially available prosthesis to the

trochlea (fig. 6). In these cases the option is to

consider a TKR rather than a PFR or to design

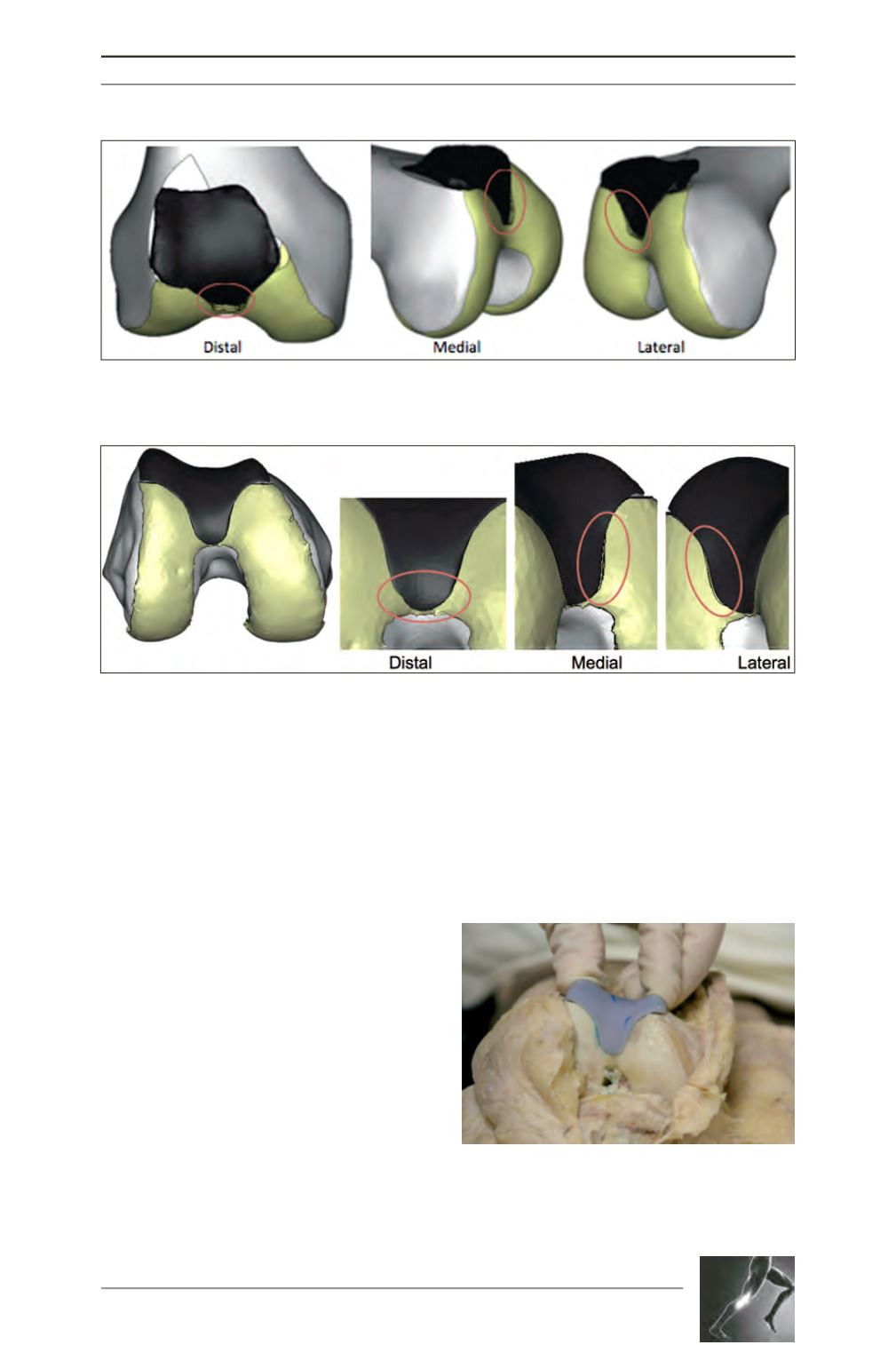

a patient-specific prosthesis. Patient-specific

prostheses need to be designed within

predetermined parameters concerning things

like; the trochlear angle; trochlear depth;

medial-lateral dimension; and medial and

lateral anterior-posterior dimensions (fig. 7).

At present the patient-specific prosthesis

manufactured by CNC (computer numerical

control) techniques are relatively slow and

expensive because, the machines have to be

specifically calibrated and set up tomanufacture

a single part. In future use it will be made of

rapid or additive manufacturing, which are

already in use in the aeronautical industry. As

the costs come down, it would become an

attractive option because these machines are

particularly suited for making once off products

(fig. 8).

Fig. 6: An example of the misfit between a commercially available off the shelf prosthesis on the femur. The

distal fit is compromised.

Fig. 7: Patient-specific prosthesis can ensure a smooth transition between the prosthesis and the patient’s

articular cartilage on distal, medial and lateral without compromising the trochlear groove alignment.

Fig. 8: Patient-specific PFR implantation was

performed using patient-specific instrumentation.

The prosthesis and the surgical instruments were

manufactured using rapid prototyping (additive

manufacturing).